Project Goal: Pioneering Sustainable Public Transport

With government support for retrofitting commercial vehicles, this project aimed to execute the complete conversion of a popular diesel-powered city bus, the Eicher 10.75H Skyline, into a zero-emissions electric platform. The primary objective was to develop a systematic, well-documented process for such a large-scale conversion, addressing key challenges in powertrain architecture, structural integrity, and digital modeling to ensure a safe, reliable, and efficient outcome.

My Role: Engineering Team Member

As part of a dedicated team under the guidance of Prof. Bivek Baral, I played a key, hands-on role in the core engineering tasks of this multi-faceted project. My responsibilities were critical to moving from a diesel bus to a validated electric design:

- 3D Scanning & Digital Twin Creation: Actively involved in the ongoing, detailed 3D scanning of the bus to create a precise digital model, which is the foundation for all subsequent design and analysis.

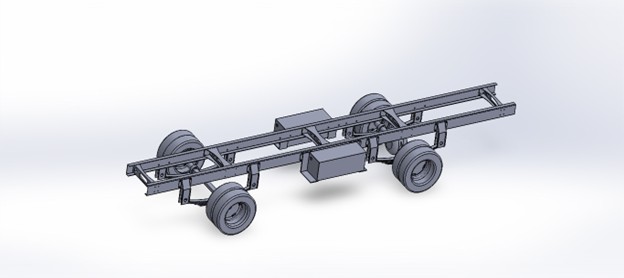

- Computer-Aided Design (CAD): Designed the 3D models of the bus chassis and new EV components (motor mounts, battery packs) using SolidWorks 2022 R1 based on precision measurements.

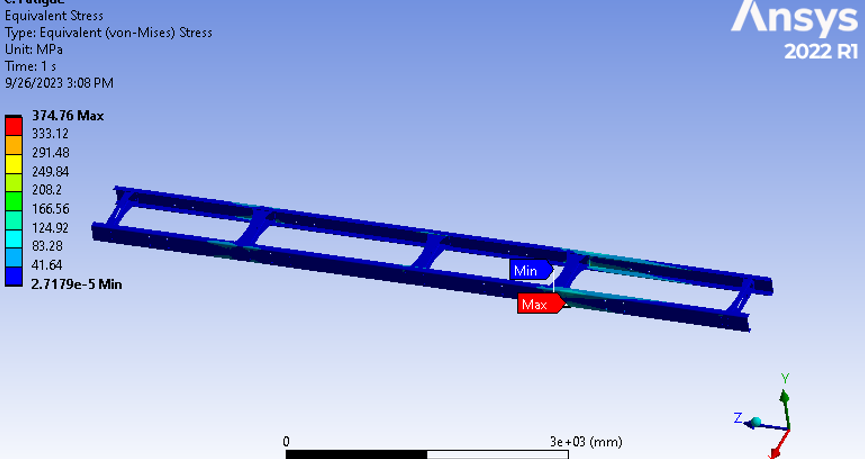

- Finite Element Analysis (FEA): Conducted structural analysis of the bus's ladder frame chassis in ANSYS, simulating both Gross Vehicle Weight (GVW) and 25% overload conditions to validate its structural integrity for the new powertrain.

- Systematic Disassembly: Participated in the physical disassembly of the diesel engine, transmission, and fuel systems, adhering to strict safety protocols and documenting the process.

The Conversion Process: A Blend of Digital and Physical Engineering

This project follows a rigorous workflow that combines physical disassembly with advanced digital simulation to ensure a successful and safe conversion.

1. Digital Design & Chassis Modeling

The process began in the digital realm. I created a precise CAD model of the Eicher bus's C-channel ladder frame chassis in SolidWorks. This model served as the master blueprint for planning the placement of the new electric motor, battery packs, and controller, ensuring a perfect fit and balanced weight distribution before any physical work began.

2. Structural Integrity Validation (FEA)

To guarantee the chassis could handle the new weight and torque characteristics of the electric powertrain, I performed a Finite Element Analysis in ANSYS. The simulation confirmed that the chassis can safely support the Gross Vehicle Weight (GVW) and even a 25% overload with minimal deformation (max 6.85 mm), validating the frame's robustness for the conversion.

3. Physical Disassembly and Preparation

With the digital design validated, the team undertook the systematic disassembly of the diesel powertrain. Following strict safety procedures, the engine, fuel tank, and exhaust systems were carefully removed, a process that took 4 days. This crucial step prepared the bus chassis for the installation of the new, clean electric drive system.

Current Status & Next Steps

This project represents a significant step forward in developing practical, sustainable transportation solutions for Nepal. The digital design and structural validation phases are complete, and the physical disassembly has prepared the vehicle for its electric transformation.

- Validated Chassis Design: Confirmed through FEA that the existing ladder frame is more than capable of handling the electric conversion.

- Completed Digital Twin Foundation: The ongoing 3D scanning is creating a high-precision digital model essential for future optimization and documentation.

- Systematic Workflow Established: Created a documented, safety-conscious process for heavy vehicle powertrain disassembly.

- Next Steps: The next phases involve the integration of the electric motor, fabrication of battery enclosures, high-voltage system wiring, and comprehensive on-road testing.